Dekko

Dekko

Solutions™

Contract Manufacturing

When performance and reliability matter most, Dekko delivers.

North American Manufacturing

MADE HERE. BUILT BETTER.

Dekko Solutions delivers precision manufacturing across North America, with over 630,000 square feet of U.S.-based production capacity in Indiana, Alabama, North Carolina, and Texas. Our strategically located facilities provide faster lead times, supply chain stability, and compliance with U.S. quality standards.

With additional capacity in Mexico, we offer scalable production while maintaining North American oversight and quality assurance. Whether you need metal fabrication, wire harness assembly, injection molding, or testing and certification, our facilities are designed to meet your needs and drive your success.

Contract Manufacturing Capabilities

From precision design through scalable manufacturing, we bring your vision to life—efficiently, reliably, and without compromise.

Dekko Solutions is your trusted leader for contract manufacturing, offering precision-driven, scalable production capabilities to meet the diverse needs of industries worldwide. With a focus on efficiency, quality, and reliability, we ensure that our customers receive cost-effective solutions without compromising on performance, helping them stay competitive in a fast-paced ever-changing market.

Design & Engineering Support

We partner early to optimize performance, cost, and manufacturability, accelerating your path from concept to production.

Lab Testing & Product Validation

Our in-house testing ensures compliance and performance through rigorous mechanical, electrical, and environmental validation

Injection Molding

From standard molds to overmold and multi-press, we create durable, integrated plastic components tailored to your application.

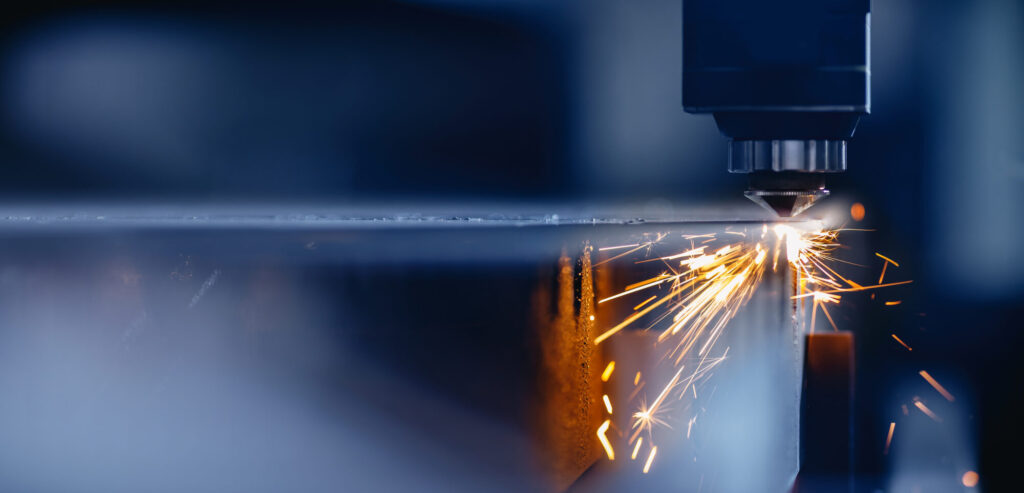

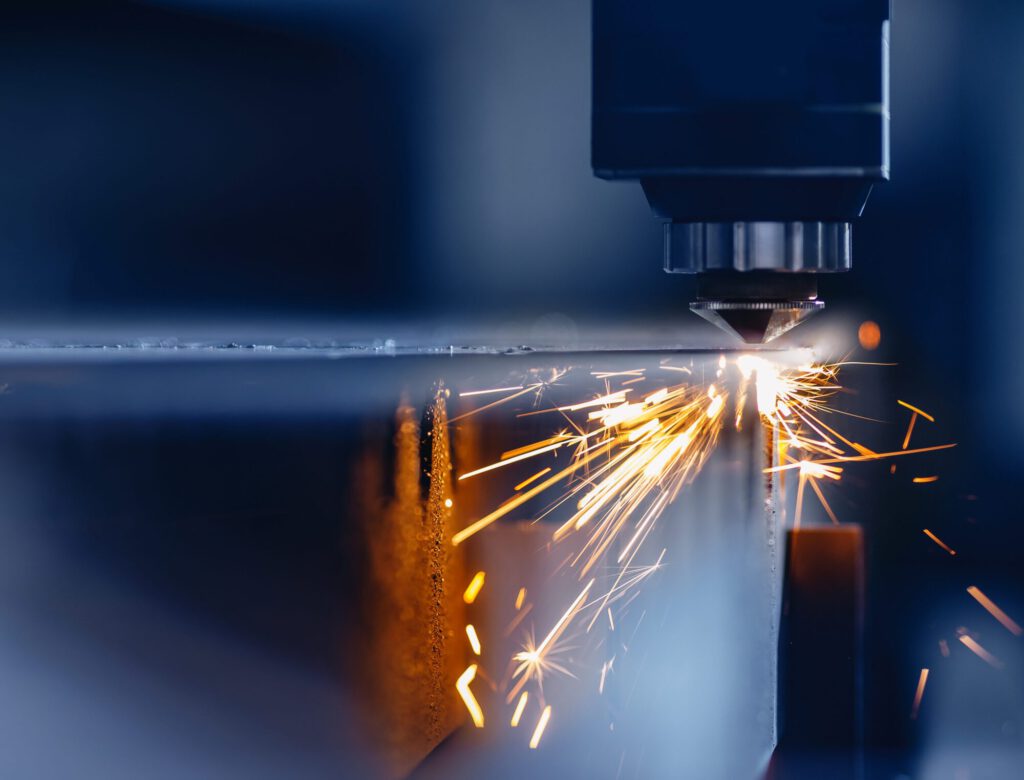

Metal Fabrication

CNC machining, laser cutting, bending, stamping, riveting, welding, and finishing—all executed with precision for structural and custom metal components.

Wiring Manufacturing

Coating, winding, stamping, and braiding—our wire processing delivers consistent performance across electrical systems.

General Assembly

Cut-to-length preparation, terminal assembly, large harness boards, and mechanical builds—we simplify complexity with turnkey assembly solutions.

Finishing & Aesthetics

Final paint, trim application, and surface treatments elevate form and function, ensuring your product is ready for market.

Partnering Across Industries

Trusted by Industry Leaders to Build What’s Next.

Components, Assembly, Finished Good

Transportation

Healthcare

Dekko supports medical device OEMs with high-precision, U.S.-based manufacturing that prioritizes quality, traceability, regulatory compliance, and scalability. Our solutions are built for both clinical and home healthcare applications, where quality and reliability are paramount.

Household and Commercial Appliance

Industrial & Commercial

Lighting

Why Dekko

End-to-End Contract Manufacturing & Design

Dekko Solutions is your trusted partner for end-to-end contract manufacturing and design. We help OEMs accelerate time to market with innovative, scalable solutions—backed by U.S.-based precision, quality, and operational excellence. From concept to full-scale production, we manage the entire product lifecycle with speed, reliability, and a commitment to your success.

Design & Engineering Services

Collaborate with our skilled engineers to transform concepts into production-ready designs.

Advanced Manufacturing Solutions

Delivering precision, scalability, and speed to market through end-to-end manufacturing expertise.

Discover Advanced manufacturing Solutions

Get Started

Ready to take your manufacturing to the next level? Contact us to learn more about our services or to get started on your next project.